Testing Facilities

To help us manufacture paints as per prominent IS & ASTM standards

The following are some of our advanced testing facilities for paint manufacturer

A spectrophotometer is a device that precisely measures electromagnetic energy at specific wavelengths of light. It uses the characteristics of light and energy to identify colors and determine how much of each color is present in a ray of light. The instrument helps achieve ΔE < 0.3 ensuring zero batch-to-batch variation in colors and tones.

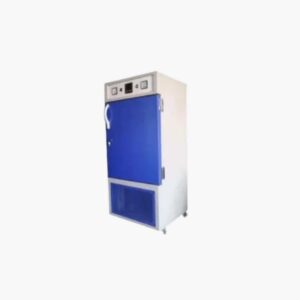

A humidity chamber is a vital testing instrument for analyzing the prolonged effect of humidity on components to fix its quality parameters. This instrument is not subjected to only one industry application. It is used in auto, capital goods, and general industries for quality assurance testing.

Relevant standards: ASTM D 870, ASTM D 2247

Salt Spray Test (SST) is a widespread method to test the resilience of coatings against corrosion. This test is an accelerated corrosion test that produces a corrosive attack on coatings to evaluate, after a pre-determined period, whether it can be used as a protective finish.

Relevant standards: ASTM B 117

Cyclic corrosion testing is intended to be a more realistic way to perform salt spray tests than traditional, steady-state exposures. It exposes specimens to a series of different environments in a repetitive cycle for eg. cycling between salt fog and dry conditions.

Relevant standards: ISO 7253, ISO 9227

The flow Curtain coating process creates an uninterrupted curtain of fluid that falls onto a substrate. The object to be coated, such as door panels, is passed along the conveyor at a controlled and continuous speed so as to receive an even coating on its upper face.

Colorimeter helps capture precise color values in RGB, CMYK, etc. formats. It is a portable instrument to help measure colors when visiting customers.